Produsen Rel Baja Standar JIS

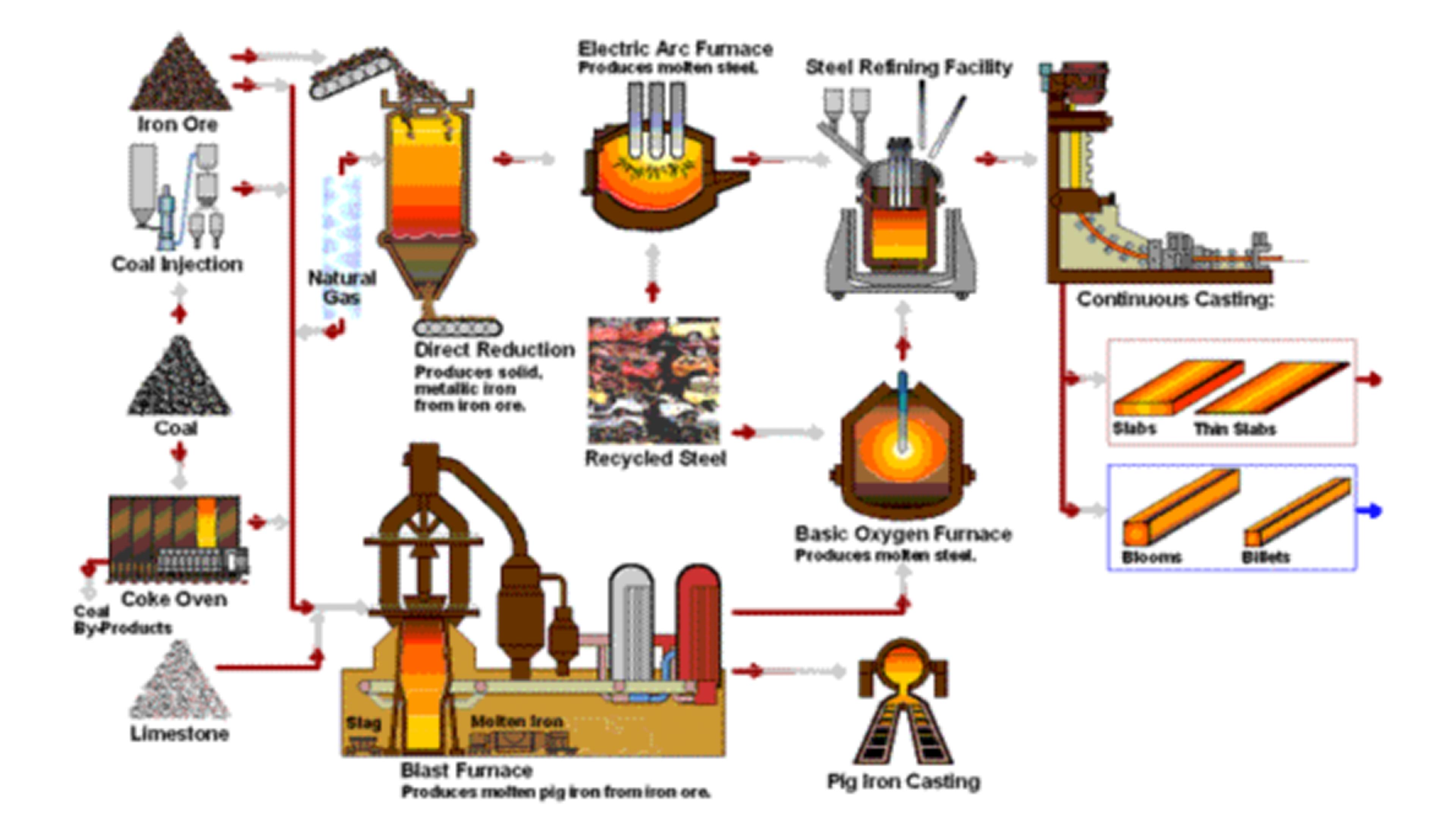

PROSES PRODUKSI PRODUK

Kondisi stres dariRel baja JISRel kereta api relatif kompleks. Selama penggunaan, ujung rel mengalami beban benturan periodik. Di bawah pengaruh roda kereta, permukaan rel mengalami tegangan kontak, gesekan gelinding selama pengoperasian lokomotif, dan gesekan geser selama pengereman. Bentuk utama kerusakan pada rel meliputi patahan, keausan permukaan, dan lain-lain. Untuk menyesuaikan dengan kebutuhan transportasi kereta api berkecepatan tinggi dan bermuatan berat, serta untuk memastikan stabilitas, kenyamanan, keselamatan, dan efisiensi operasional yang tinggi dari kereta api berkecepatan tinggi selama pengoperasian.

Jenis rel standar dinyatakan dalam kilogram massa rel per meter panjangnya. Rel yang digunakan di jalur kereta api negara saya meliputi 75kg/m, 60kg/m, 50kg/m, 43kg/m, dan 38kg/m.

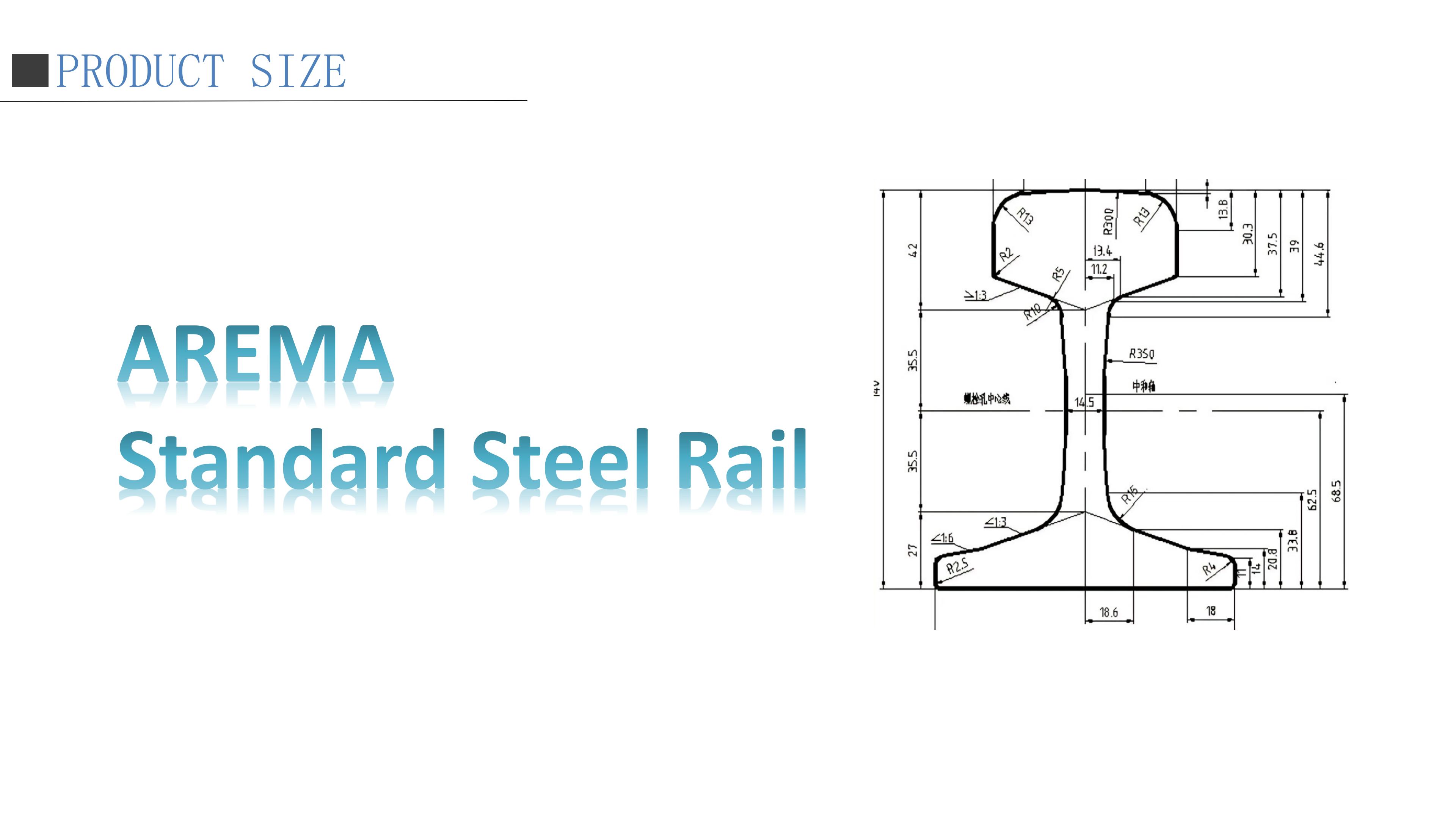

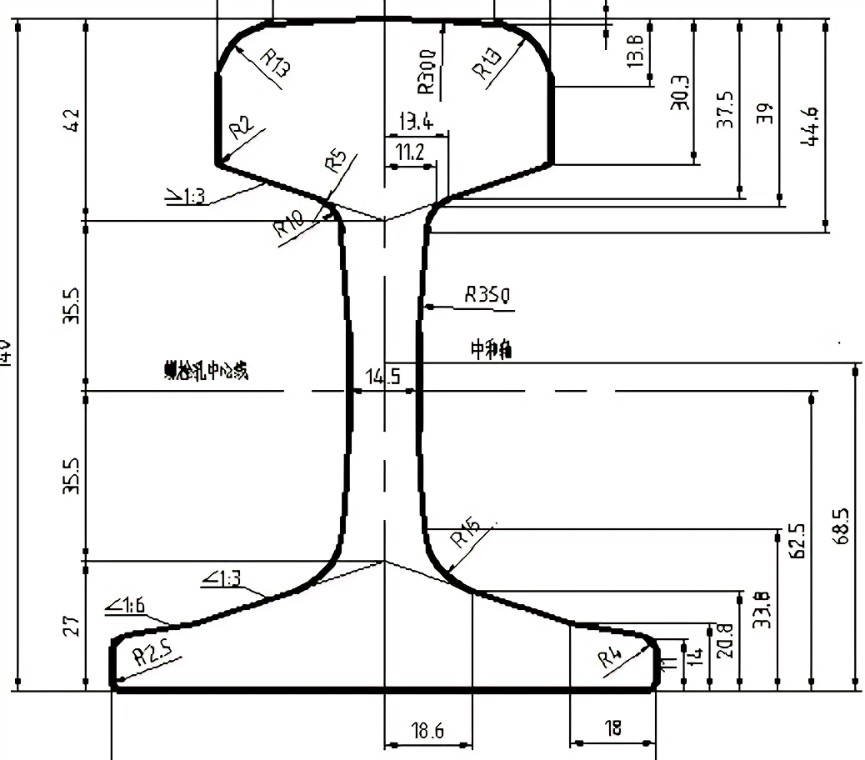

UKURAN PRODUK

1. Harus memiliki ketahanan aus yang tinggi dan kekuatan yang tinggi.

2. Untuk memiliki ketahanan lelah yang baik, terutama ketahanan lelah kontak yang baik, selain kekuatan yang tinggi, juga perlu memiliki kebersihan yang tinggi.

3. Memiliki performa pengelasan yang baik sehingga memerlukan penggunaan jalur tanpa sambungan.

4. Harus memiliki ketahanan terhadap patahan yang baik untuk memastikan keamanan dan keandalan pengoperasian sistem perkeretaapian.

5. Memiliki kelurusan dan akurasi dimensi yang tinggi.

| Rel kereta api Jepang dan Korea | ||||||

| Model | Tinggi rel A | Lebar bawah B | Lebar kepala C | Ketebalan pinggang D | Berat dalam meter | Bahan |

| JIS15KG | 79,37 | 79,37 | 42,86 | 8.33 | 15.2 | ISE |

| JIS 22KG | 93,66 | 93,66 | 50.8 | 10,72 | 22.3 | ISE |

| JIS 30A | 107,95 | 107,95 | 60.33 | 12.3 | 30.1 | ISE |

| JIS37A | 122,24 | 122,24 | 62,71 | 13.49 | 37.2 | ISE |

| JIS50N | 153 | 127 | 65 | 15 | 50.4 | ISE |

| CR73 | 135 | 140 | 100 | 32 | 73.3 | ISE |

| CR 100 | 150 | 155 | 120 | 39 | 100.2 | ISE |

| Standar produksi: JIS 110391/ISE1101-93 | ||||||

Rel kereta api Jepang dan Korea:

Spesifikasi: JIS15KG, JIS 22KG, JIS 30A, JIS37A, JIS50N, CR73, CR 100

Standar: JIS 110391/ISE1101-93

Bahan: ISE.

Panjang: 6m-12m 12,5m-25m

FITUR

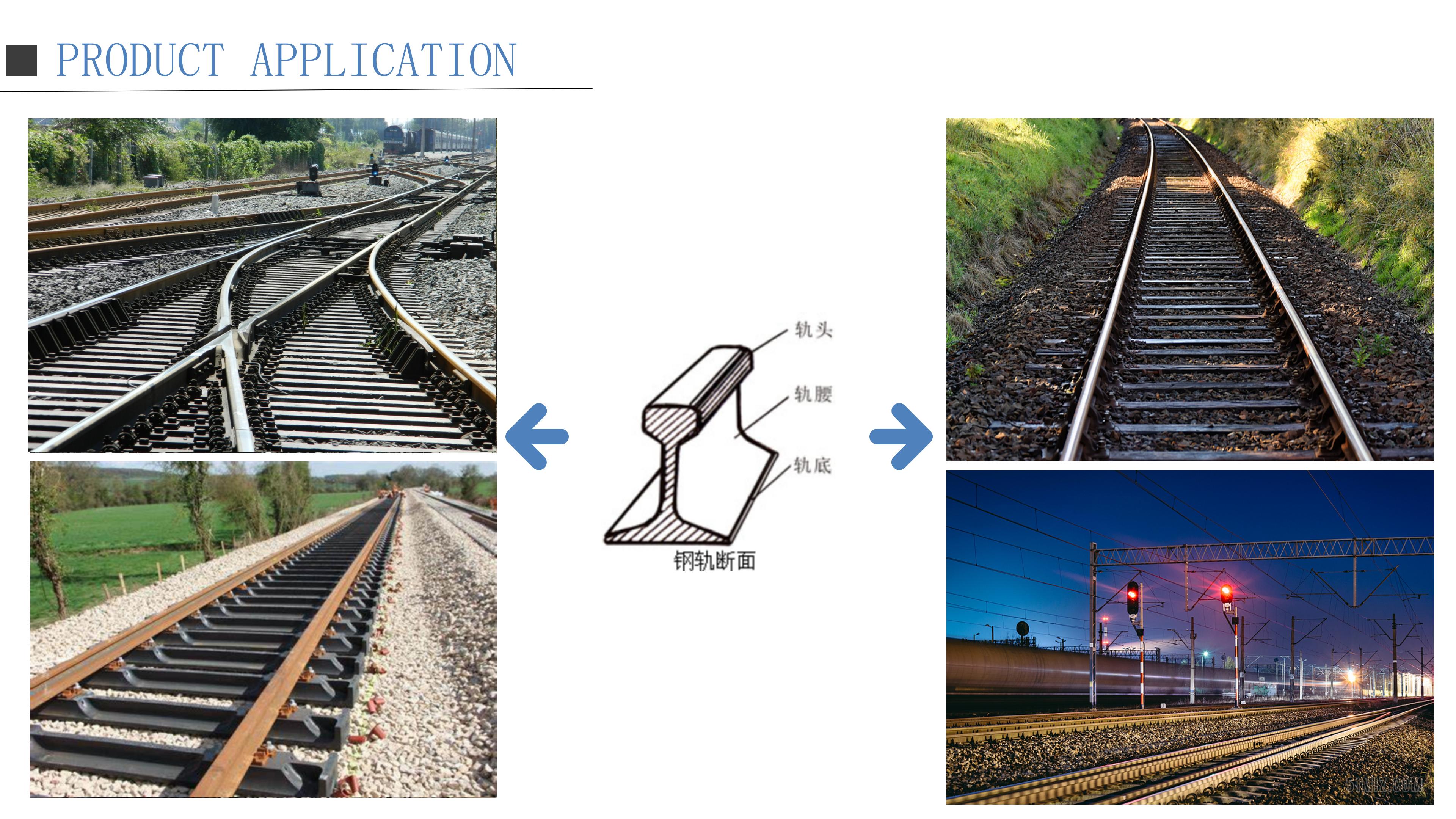

Fungsi dariRelRel berfungsi untuk memandu roda kereta api ke depan, menahan tekanan besar dari roda, dan meneruskannya ke bantalan rel. Pada jalur kereta api yang dialiri listrik atau bagian blok otomatis, rel juga berfungsi sebagai sirkuit jalur.

Rel baja juga memiliki kemampuan pengelasan dan plastisitas yang baik. Hal ini memungkinkan baja rel beradaptasi dengan berbagai bentuk dan kelengkungan, sehingga memudahkan konstruksi. Baja rel dapat diproses melalui pengelasan, pembengkokan dingin, dan metode pemrosesan lainnya untuk memenuhi kebutuhan berbagai bentuk rel dan desain jalur.

PENGEMASAN DAN PENGIRIMAN

Hal ini tidak hanya dapat memastikan kelancaran transportasi, tetapi juga meningkatkan keselamatan kereta api dan kenyamanan perjalanan. Di masa depan, dengan perkembangan dan peningkatan pesat transportasi rel baja standar UIC, rel baja akan terus beradaptasi dengan kebutuhan baru dengan karakteristik dan keunggulannya yang unik, memberikan pengalaman transportasi yang lebih efisien, aman, dan nyaman bagi masyarakat.

KONSTRUKSI PRODUK

Pertanyaan yang Sering Diajukan (FAQ)

1. Bagaimana saya bisa mendapatkan penawaran harga dari Anda?

Anda dapat meninggalkan pesan kepada kami, dan kami akan membalas setiap pesan tepat waktu.

2. Apakah Anda akan mengirimkan barang tepat waktu?

Ya, kami berjanji untuk menyediakan produk berkualitas terbaik dan pengiriman tepat waktu. Kejujuran adalah prinsip perusahaan kami.

3. Bisakah saya mendapatkan sampel sebelum memesan?

Ya, tentu saja. Biasanya sampel kami gratis, kami dapat memproduksi berdasarkan sampel atau gambar teknis Anda.

4. Apa ketentuan pembayaran Anda?

Ketentuan pembayaran standar kami adalah uang muka 30%, dan sisanya dibayar setelah menerima B/L (Bill of Lading). EXW, FOB, CFR, CIF.

5. Apakah Anda menerima inspeksi pihak ketiga?

Ya, tentu saja kami menerima.

6. Seberapa besar kami bisa mempercayai perusahaan Anda?

Kami telah berspesialisasi dalam bisnis baja selama bertahun-tahun sebagai pemasok andal, berkantor pusat di provinsi Tianjin, silakan datang untuk melakukan investigasi dengan cara apa pun.